The cement industry in Pakistan carries on to evolve amid increasing design desire and financial fluctuations.

This post gives an in-depth take a look at cement level currently in Pakistan, value comparisons with former months, variables influencing the industry, and traits throughout different areas. Whether you are a builder, contractor, or homeowner, understanding cement price in Pakistan is important for budgeting and job scheduling.

What Are the Current Selling prices?

What's the Cement Level in Pakistan?

The cement rate in Pakistan ranges from PKR one,two hundred to PKR 1,400 for every 50 kg bag. This charge may well range based on the cement manufacturer, location, and transportation expenses. Significant city centers including Karachi, Lahore, and Islamabad often working experience marginally higher costs because of logistical expenses and increased demand from customers for cement.

Listed here’s A fast overview of common costs:

Model Cost per 50 kg Bag (PKR)

Fortunate Cement 1,280

DG Cement one,250

Fauji Cement one,230

Maple Leaf Cement 1,270

Dewan Cement 1,200

What Aspects Affect The present Cement Fees?

Many things influencing cement costs Engage in a task:

Fuel & Vitality Charges: Cement production is Electricity-intense. Fluctuations in oil and gasoline rates right have an impact on the cost of cement in Pakistan.

Raw Materials Availability: Crucial factors such as gypsum, clinker, and limestone are getting to be costlier, influencing the expense of cement.

Seasonal Demand: Throughout peak design months (spring and summertime), cement need surges, boosting charges.

Forex Exchange Amount: Imported Uncooked elements grow to be dearer once the rupee weakens from the greenback.

Government Guidelines: Responsibilities, taxes, and import polices also influence the cement amount nowadays in Pakistan.

These elements collectively establish how cement prices shift month by month throughout Pakistan.

Cement Cost in Pakistan: Comprehension the industry Traits

Exactly what are the most up-to-date Cement Prices in Pakistan?

The latest cement prices in Pakistan vary between PKR one,200 and PKR one,400 per bag, affected via the manufacturer, distance from creation models, and native supply chains. Cement brand names in Pakistan like Blessed Cement, DG Cement, and Fauji Cement retain reliable excellent, which frequently justifies their top quality pricing.

Exactly what are the today cement rate in pakistan Predictions for Cement Selling prices while in the Upcoming Months?

The cement industry in Pakistan is anticipated to stay stressed from worldwide gasoline rates and inflation. Analysts predict that cement premiums might maximize marginally or keep on being stable in coming months Except if major modifications arise in gasoline tariffs or Uncooked product Price dynamics.

Variables which will affect long run pricing:

Article-election financial reforms

Fuel subsidy policies

Worldwide commodity charges

A stabilization or reduction in fuel rates could lead to lessen prices as a consequence of lessened generation and logistics charges.

So how exactly does Desire Have an effect on the cost of Cement in Pakistan?

Desire for cement peaks in the course of Lively building seasons, which include March by way of September. In the course of these durations, cement prices in Pakistan cement price in pakistan may perhaps climb resulting from confined offer and enhanced orders. Conversely, off-period months can see stabilized or slightly lowered prices.

Huge infrastructure and housing projects underway across towns like Lahore, Islamabad, and Karachi carry on to contribute to strong cement demand, pushing the market towards higher charges.

Forms of Cement Readily available in Pakistan: Which Ought to You Choose?

Exactly what are the different sorts of Cement Obtainable in Pakistan?

Pakistan provides a range of cement styles catering to varied building tasks:

Normal Portland Cement (OPC): The most often made use of sort of cement for standard structures.

Portland Pozzolana Cement (PPC): Offers improved toughness and resistance to chemical assaults.

Slag Cement: Produced working with blast furnace slag, perfect for industrial buildings.

White Cement: Aesthetic cement Utilized in tiles, flooring, and decoration.

Hydraulic Cement: Quickly sets when blended with h2o, well suited for h2o-retaining constructions.

These types of cement provide distinctive roles, and selecting the proper 1 is determined by development demands, environmental disorders, and preferred toughness degrees.

Mackenzie Rosman Then & Now!

Mackenzie Rosman Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now! Batista Then & Now!

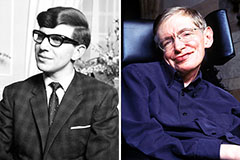

Batista Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!